Clay and Pottery

An ancient art

by Phyllis McKee |

Clay on a potter's wheel Famous PottersRelated Links |

Since the first piece of clay fell into a fire and was transformed into a glasslike material, people have used clay for domestic wares, ritual tokens, and decorative items. The oldest known pottery fragments stem from the Hittite civilization, 1400-1200 B.C.

Where Clay Comes From

Clay comes from the ground, usually in areas where streams or rivers once flowed. It is made from minerals, plant life, and animals—all the ingredients of soil. Over time, water pressure breaks up the remains of flora, fauna, and minerals, pulverizing them into fine particles. Larger particles are filtered out through rocks and sand, leaving silt to settle into beds of clay. How far silt travels from its source and how pure the silt is determines the type of clay it becomes.

Kinds of Clay

The three most common types of clay are earthenware, stoneware, and kaolin. Earthenware, or common clay, contains many minerals, such as iron oxide (rust), and in its raw state may contain some sand or small bits of rock. Earthenware is a secondary clay that has been transported by moving water some distance, picking up minerals and other materials before settling in a river bed. Because of its many impurities, earthenware melts at a cooler temperature than other clays. Called a low-fire clay, earthenware fires (or bakes) in a temperature range of 1700 to 2100°F (926–1150°C). After firing, it is still porous and—unless glazed—is often white or gray. Earthenware is commonly used in the making of terra cotta pots, roofing tiles, and other low-fire ware.

Stoneware is a hard and durable clay that is fired to temperatures between 2100 and 2300°F (1205–1260°C). Its natural colors vary from light gray or tan to dark gray or chocolaty brown. Historically stoneware was used for crocks and jugs and is now typically used to make dinnerware.The purest clay is kaolin, or china clay. Called a primary clay because it is found very near its source, kaolin has few impurities and is the main ingredient used in making porcelain. Because its particle size is larger than other clays, it is not very plastic. This means that in a moist unfired state, kaolin tears when it is bent. Kaolin is a high-fire clay, needing heat from 2335 to 2550°F (1280-1400°C), to vitrify. Fired porcelain can become very hard and translucent, its melted surface becoming so smooth and shiny that a glaze is not needed.

Techniques for Making Pottery

The earliest method for making bowls and jugs is handbuilding—using only hands and clay. This approach is still used today. A ball of clay is pinched or pressed to form a bowl. Or the clay is rolled into ropes or coils that are then wrapped in upward circles until the desired height is reached. The coils are then often smoothed so that they are no longer distinct.

Clay coils |

Another handbuilding method is slab-building. A large ball of clay is flattened into a pancake-like slab. The slab is then cut into rectangles, which are attached together by moist clay, making the sides of a clay box. To make a bowl, the entire slab is placed over a round mold.

Around 5000 B.C. the potter's wheel was invented, probably by the Sumerians of the Tigris-Euphrates basin or by the Chinese. The potter's wheel allows the potter to throw even, symmetrical shapes in much less time and with far less effort. They are thought to have been in operation even before wheels were used for transportation.

There are many different types of potter's wheels in use. Some are powered by hands or feet, which spin the platter on which the clay sits. Others use treadles, like the foot pumps seen on old sewing machines. Many wheels are turned by electricity.

And Now, the Fire

After a piece of pottery has been formed and dried completely, it must be fired to achieve permanency. Without the chemical transformation that occurs through firing, an uncooked bowl dissolves back into mud once it comes in contact with water.

Bottle kilns. Used by permission of Gladstone Pottery Museum, Stoke, UK. |

Giant bottle kilns fueled by coal were commonly used to fire clay in the 18th and 19th centuries, and the first half of the 20th century, and have been replaced by cleaner fuels like natural or propane gas, wood, and electricity.

Some people fire their work in pits in the ground. They layer the pots with hay, seaweed, or other combustibles. The fire burns from top to bottom over the course of a day or two. The chemicals in the hay, or other chemicals that are added to the fire, are absorbed into the pot and create colors in the clay.

Wood-fired Pottery

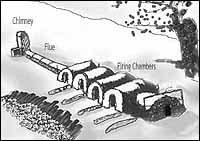

The Japanese have created clay art for thousands of years. They are famous for their wood-fired pottery, fired in an anagama (a single-chamber, tunnel-shaped kiln) or a noborigama (a multi-chamber kiln). The use of these wood-fired kilns has spread worldwide.

Noborigama kilns |

These specialized wood firings can take up to a week to complete. The fire is started with tiny pieces of wood and the kiln is stoked every five minutes. When the kiln becomes hot, large pieces of pottery are added at regular intervals. The fire is kept burning 24 hours a day for several days until the clay has matured. The kiln is left to cool for several more days—if it is opened too soon, the pots will crack and break. Because it is so labor-intensive, potters who use these kilns often fire only once a year. They save up an entire year's work, perhaps hundreds of pots, for one firing.

Most wood-fired pottery doesn't have a glaze. As the fire gets hotter, drafts pull wood ash through the kiln where it is deposited on the pots. The pots are so hot from the flames (they glow red like charcoals in a barbecue) that the ash melts on the clay and creates its own glaze. The patterns produced are unpredictable.